Automatic bar screen: Why does the strap outperform cable and chain?

In the field of water pretreatment, the choice of an automatic bar screen is strategic. While the function remains the same — extracting screenings to protect downstream equipment — the lifting mechanism changes everything. Long dominated by cable or chain, the strap has emerged as the most reliable and cost-effective solution in operation.

Here is why choosing a strap-operated bar screen is the best choice for your operations.

Unrivaled mechanical reliability

The main flaw of the cable is its unpredictability. A cable can wind unevenly on the drum, overlap, or slip out of its groove, causing untimely safety shutdowns.

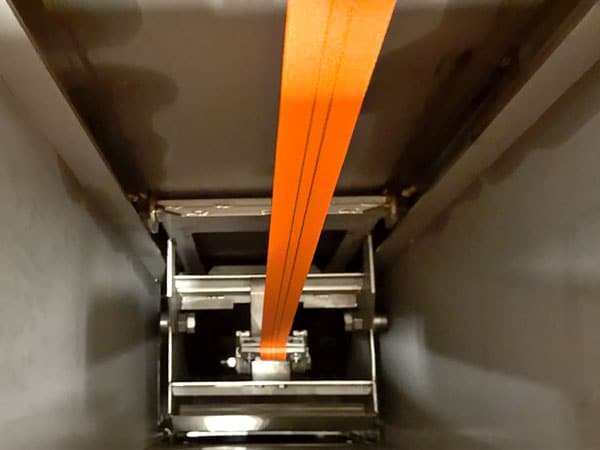

The strap, thanks to its flat shape, guarantees perfect winding with every cycle. It provides a wide and stable contact surface, eliminating the risk of derailment or mechanical blockage related to the lifting system.

Maintenance: The strap's strong point

This is where the difference is most striking. For an operator, maintenance time is a major hidden cost.

Zero lubrication: Unlike the chain, which requires constant lubrication (often polluting the effluent), the synthetic strap operates dry. No grease, no corrosion, no friction wear in loaded water.

Cleanliness and hygiene: Working on a strap mechanism is much less arduous for technicians than handling heavy and fouled chains.

Replacement in record time

This is undoubtedly the ultimate argument for your plant's availability.

Replacing a chain is a heavy operation: often-seized links must be detached, which can immobilize the equipment for half a day. As for the cable, it requires precise fastenings and sometimes specific crimping tools.

The FB Procédés strap can be changed in a matter of minutes. Lightweight, flexible, and easy to secure, this component allows for an almost immediate return to service of the installation. This ease of maintenance drastically reduces your operating costs and the labor strain on your maintenance teams.

Resistance and environmental durability

The strap used on our bar screens is designed to withstand the most aggressive environments (H2S, constant humidity, pH variations).

No corrosion: Unlike metal cables that eventually fray due to oxidation.

Quiet operation: No more metallic clattering noise from chain links; the strap ensures smooth and silent operation, a real advantage for plants located near residential areas.

Conclusion: A profitable investment

While the choice of a bar screen is often based on the purchase price, it is the Total Cost of Ownership (TCO) that should guide your decision. Thanks to its ease of replacement, the absence of lubrication, and its longevity, the strap bar screen is, in the long term, much more economical than a cable or chain system.

Do you wish to modernize your pretreatment? Contact the experts at FB Procédés for a personalized study of your installation.

Related articles

Dégrilleur automatique : Pourquoi une sangle surclasse-t-elle un câble ou une chaîne ?

Dégrilleur automatique : Pourquoi la sangle surclasse-t-elle le câble et la chaîne ? Dans le domaine du prétraitement des eaux, le choix d’un dégrilleur automatique

Retrouvez FB PROCÉDÉS au Carrefour de l’Eau 2026 à Rennes

FB PROCÉDÉS expose ses innovations au Carrefour de l’Eau 2026 La 27ème édition du Carrefour de l’Eau se tiendra à Rennes les 21 et 22

73rd bar screen installed in Vendée

73ème dégrilleur installé en Vendée Le mois dernier, nous avons donc participé à la mise en route d’un dégrilleur automatique de type NG11, associé à